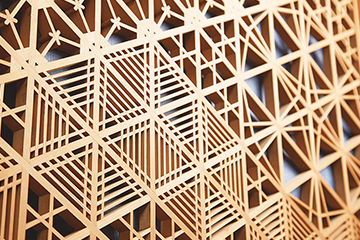

Overview of producing areas

Kishu bamboo fishing rods

Overview of producing areas

Kishu bamboo fishing rods

Overview

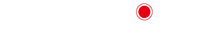

Scenes of work

Materials assembly

The use of madake (Phyllostachys bambusoides) for the rod end, koya-chiku (Sasamorpha borealis) for the middle section, and yadake (arrow bamboo) for the sections called sanban and moto, is standard practice. The length and thickness of bamboo, the springiness, the flexibility, and other factors are examined.

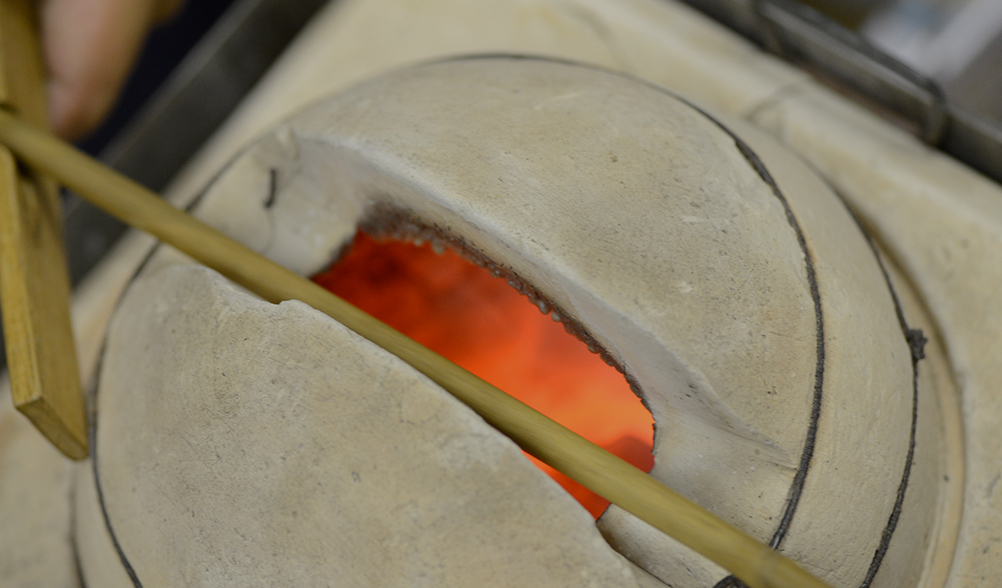

Firing

This is the task of exposing unworked bamboo to flame to work out warped areas. A tool called a tamegi is used to straighten the bamboo and enhance its inherent resilience.

Rod end shaving

The rod end is shaved with blades and files to bring out the optimal balance. The handle is given a design that incorporates traditional techniques such as rattan, dried lacquer, and raden (mother-of-pearl inlay).

Lacquer coating and finishing of the body

The ends of rod sections are reinforced with silk thread, and lacquer coating and polishing are repeated. A coating of lacquer called shiageme is applied to the cut end of the branch. Finally, lacquer is layered on the body of the rod overall, heating is applied to the finish, and the rod is completed.

Traditional crafts of Wakayama