Overview of producing areas

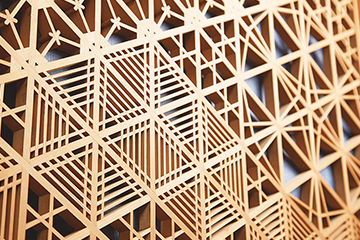

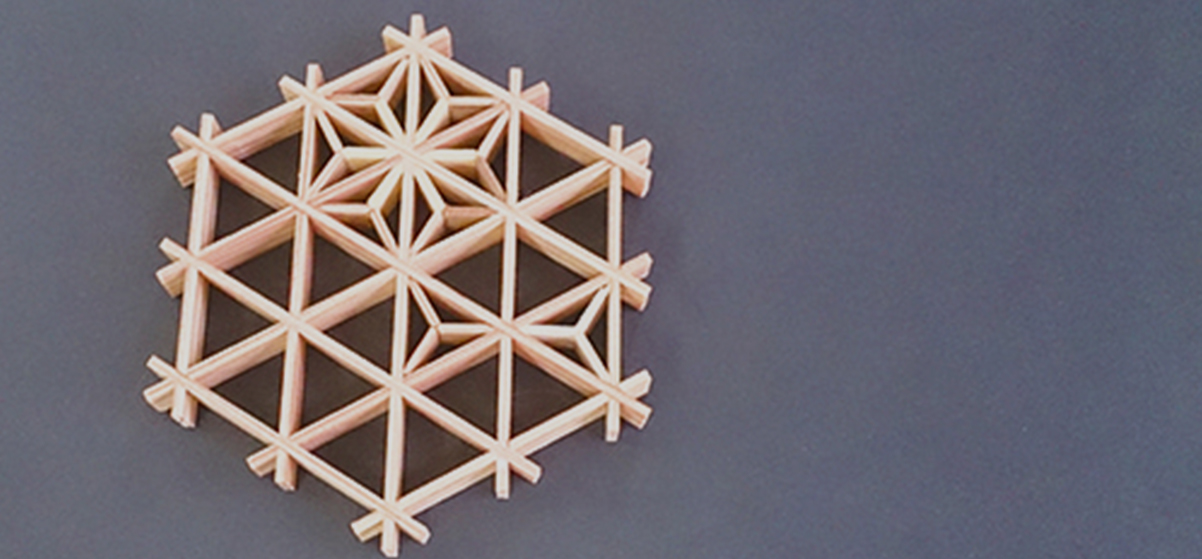

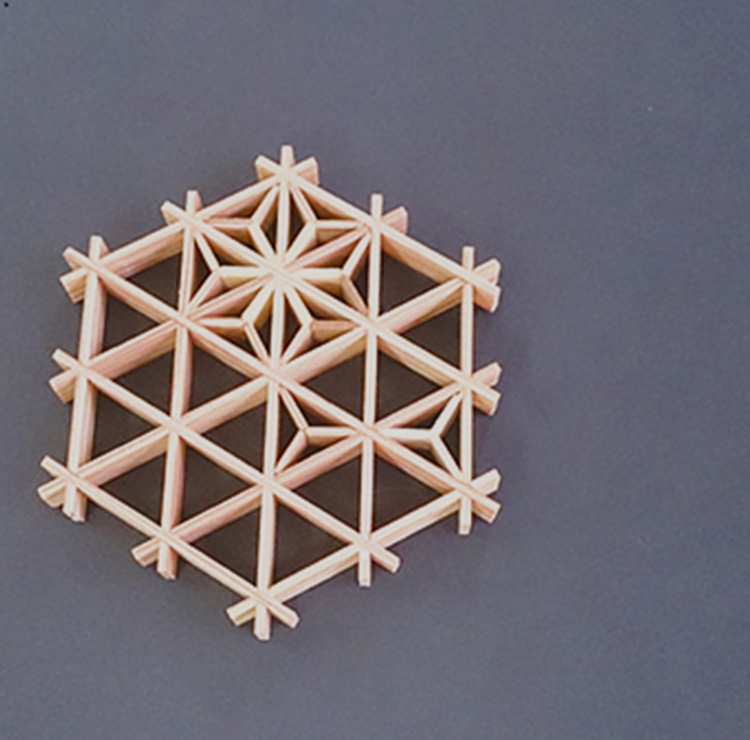

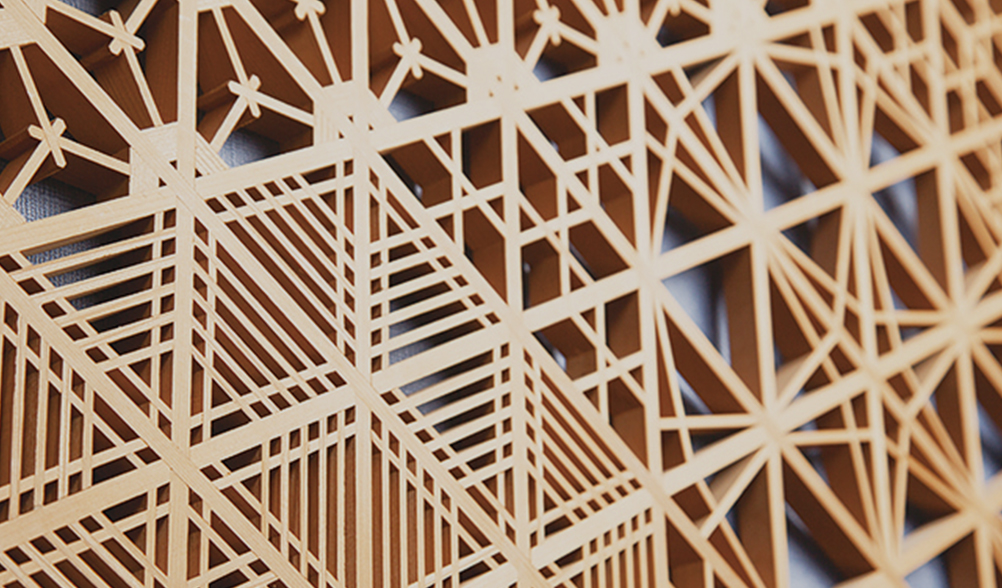

Kishu Koya Kumiko wood joinery

Overview of producing areas

Kishu Koya Kumiko wood joinery

Overview

Scenes of work

Fine splitting into the desired dimensions

Logs and thick lumber are split and sawn into specific boards. The boards are then split into desired dimensions using a circular saw bench.

Frame-making

Frame-making is performed with a homemade die table. Scraping is performed so that the finished materials can be joined. Component materials that form the canvas and those for the geometric patterns are created.

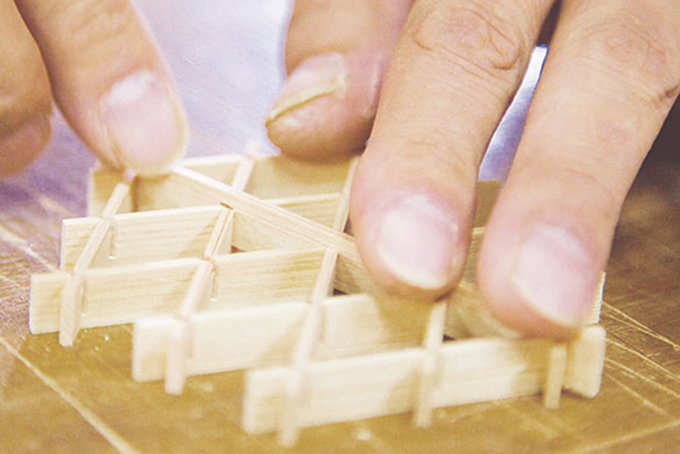

Foundation assembly

Foundation assembly is the creation of a canvas for the dimensions to be produced. Using the prepared component materials, a frame for weaving in the pattern is assembled.

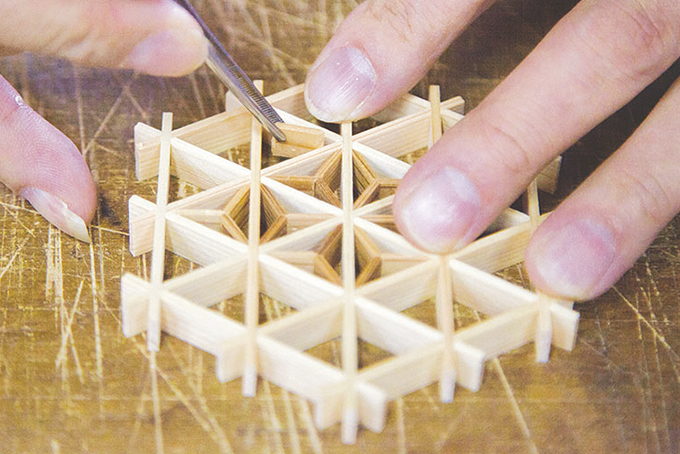

Temporary assembly to main assembly

The picture is fitted to the canvas, and wood chip crosspieces are inserted one by one. When the temporary assembly is complete, the expression in the picture is reviewed and corrected. After main assembly and fixing, the work is complete.

Traditional crafts of Wakayama